Resource Recovery Centre ♻️: How Materials Are Recycled From Waste

Resource Recovery Centre: if you have been procuring commercial waste management or recycling services for any period of time, you will have heard varying and competing claims by waste companies as to how they will recycle your waste and how they are more environmentally friendly than other operators(with better facilities etc). Today we will walk through some of the types of resource recovery centre and MRF ( Materials Recovery Facilities) and how they operate.

>Download Now: Free PDF Business Owners Guide To Commingled Recycling Bin Services

Table of contents for this article include:

I. How does a resource recovery centre actually work?

II. What is resource recovery?

III. Impact of national resource recovery on the environment

How does a resource recovery centre actually work?

The MRF or resource recovery centre promises a great future – where we can recycle very large amounts from even mixed general waste bins – removing the entire need for cardboard or commingled recycling bins at all.

A bit about Waster and how we can help your business!

Waster is a business focused on delivering low cost and flexible waste and recycling services to small and medium Australian companies. Check out our prices and services – or book online in our waste shop.

We provide all your required waste services on one simple invoice – from sanitary services to general waste bins or cardboard recycling!

How does a resource recovery centre work?

The waste industry in Australia is getting smarter every year and due to the heavy cost of dumping at landfill – due to government levies on this, and also the potential value to be gained in selling on commodities collected – more and more materials are being recycled and reused. When recycling bins such as cardboard recycling or comminged yellow bins are collected, they will be taken to a resource recovery centre. Progressively, general waste is also being taken to such facilities where it can be separated into recycling components.

MRFs are being rolled out across Australia (they were initially introduced in the US in the 1970s) by many different companies. As per Wikipedia, a MRF is :

“A materials recovery facility, materials reclamation facility, materials recycling facility or Multi re-use facility (MRF, pronounced “murf”) is a specialized plant that receives, separates and prepares recyclable materials for marketing to end-user manufacturers. Generally, there are two different types: clean and dirty materials recovery facilities.”

“A clean MRF accepts recyclable comingled materials that have already been separated at the source from municipal solid waste generated by either residential or commercial sources.” This is where your commingled and cardboard bins go.

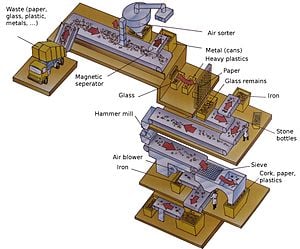

At the facility the varying commodities are separated by numerous systems including spinning, shaking mechanisms that let separate items by size, weight, density etc. The separated items are then processed for recycling.

What are the latest trends in this technology?

The latest trends and technology in resource recovery centre developments is seeing increased investment in mixed waste systems:

“A mixed-waste processing system, sometimes referred to as a dirty MRF, accepts a mixed solid waste stream and then proceeds to separate out designated recyclable materials through a combination of manual and mechanical sorting. The sorted recyclable materials may undergo further processing required to meet technical specifications established by end-markets while the balance of the mixed waste stream is sent to a disposal facility such as a landfill. Today, MWPFs are attracting renewed interest as a way to address low participation rates for source-separated recycling collection systems and prepare fuel products and/or feedstocks for conversion technologies. MWPFs can give communities the opportunity to recycle at much higher rates than has been demonstrated by curbside or other waste collection systems. Advances in technology make today’s MWPF different and, in many respects better, than older versions.”

Latest results internationally indicate that very high diversion (i.e. recycling rates) can be achieved – even as high as 90% from a modern resource recovery centre. This is very exciting for the environment as we work harder to protect the planet and our living conditions.

For a look at incineration as a possible future technology – see waste collection Sydney. Also see rubbish collection Perth for an overview of our core focus areas. See our blog on carbon neutral waste services.

See our blog that discusses how we can recycle up to 90% from general solid waste bins currently in Sydney.

Where can you fine major resource recovery centres throughout Australia:

– Darebin Resource Recovery Centre – see details here

– Buderim Resource Recovery Centre – see details here

– Bolinda Road Resource Recovery Centre – see details here

– Adelaide Resource Recovery Centre – see details here

– Kimbriki Resource Recovery Centre – see details here

– Nudgee Resource Recover Centre – see details here

– Geelong Resource Recovery Centre – see details here

– Willawong Resource Recovery Centre – see details here

– Port Phillip Resource Recovery Centre – see details here

– Ferny Grove Resource Recovery Centre – see details here

What is resource recovery?

Resource Recovery: One of the most common buzz words in the waste collection and recycling industry is resource recovery.

You sometimes may be suspect and think it a throw away term (pardon the pun) – but it really does reflect the approach of modern waste management, where companies are trying to reduce any dumping at landfill and save money through the valuable resources contained in bins.

With ever increasing landfill levies on dumping in general waste – i.e. at landfill – it makes all the sense in the world to remove as much value – from trash as possible.

At the end of the day – why pay to dump rubbish – when in theory – some of it is valuable – and could be stripped out from general waste bins – and be recycled or sold on.

We will cover some of the modern trends in this regard as below.

Is there really valuable resources – that could be recovered – in a normal bin?

The simple answer is yes.

If you think about what is contained in the average bin – there is a large proportion of valuable commodities such as metal, cardboard, plastic etc that can be recycled and sold for profit. All that is needed is the system of resource recovery or recycling facilities to filter the bin contents.

Waster offers low cost and high quality waste and recycling services to small and medium Australian businesses, through our online model. Check out our options and costs online today. Check out our pricing by clicking the blue banners at the top of bottom of this page.

So what can be valuable in a normal bin?

At one extreme – there probably is actually some very valuable things – thrown out by accident – like gold, money etc. For example – often you see newspaper reports about engagement rings being thrown away – like this one!

Obviously – that is an extreme example – but there is lots of value in your bin – and with true resource recover – it will increase all the time. Items as below:

Aluminium cans – such as for soft drinks – are valuable and can be easily recycled.

Cardboard – can be traded on international exchanges.

Food waste – can be used to produce biogas – to power cities. In fact – some people see food wase facilities as being the power stations of the future.

Timber – that can be used for mulch or compost.

Even plastic – can be recycled – or incinerated in a modern facility to produce energy – such as in Sweden or Japan. Obviously – recycling needs to be separated – see our blog on how barcodes can help.

Resource recovery – all that is lacking is the facility – and of course the money!

In many instances – even though we have Government backed resource recovery plans and strategies – we often lack the required facilities.

We raise billions in landfill levies – but we do not seem to have many new advanced facilities – for services like nappy recycling.

These are required for true and effective resource recovery in Australia.

Thankfully – alternative funding for new resource recovery is coming on stream globally in 2019 and 2020.

The technology to separate the commodities is already existing – the finance to build the resource recovery facilities has been the issue to date. An interesting article in Fortune magazine explains how investment funds are now looking at the sector. We quote from the article below:

“By this time next year a major high-tech recycling plant in Baltimore could be sorting 54,000 tons of recycled plastic materials—yogurt cups, milk cartons, plastic soda bottles— annually and servicing a 500-mile radius area across the East Coast. It will be one of the largest of its kind in the U.S.”

“The Baltimore recycling plant is one of the first projects funded by a new group called Closed Loop Fund. It has amassed $100 million from ten of the largest U.S. consumer goods companies including Walmart, Coca-Cola, PepsiCo, Johnson & Johnson, Procter & Gamble, Unilever, 3M, and Goldman Sachs.”

“The fund uses its checkbook to provide zero interest loans to cities and companies that want to build new recycling centers and projects.”

“Last year, Kaplan, Walmart’s former director of sustainability, and Ron Gonen, Mayor Bloomberg’s former New York City deputy commissioner of recycling and sustainability, founded the fund.”

“The challenge for the fund will be to pick projects that have the biggest potential impact. The recycling projects need to make money, and pay back the loans, but they also need to be large enough to make a dent in the waste stream. It could be a tricky balance.”

“But if the model is successful, it could provide a brand new way to encourage large-scale recycling.”

This looks like a very promising project and we look forward to seeing similar in recycling in Australia – particularly in regional cities (away from state capitals) where building a recycling centre can be difficult from a financial perspective.

Check out our blog on the future of resource recovery in general rubbish removal.

Our latest blog is on the new resource recovery Queensland program giving a rebate on recycled cans and containers.

Impact of national resource recovery on the environment

National Resource Recovery: the Easter holidays this year (2018) enjoyed some amazing weather and sunshine in Sydney.

Mr Waster took advantage of the warm weather to visit the beach with his family. When the sun shines – there is nowhere on earth better than the Australian coastline.

I also saw a very interesting TV show on Four Corners over the long weekend -looking at the growing issues of plastic waste in our oceans and the terrible impact it has on ocean and sea life.

Waster is an Australian waste management and recycling business with a difference.

We enable small and medium businesses to reduce their spend, whilst boosting recycling and helping the environment – all with the flexibility of 30 day agreements (so you are not locked in to a long term contract).

National resource recovery – recognising issue before it can be solved

The Four Corners programme really hit home the importance of the issue for national resource recovery. At the end of the day – if we do not recognise the problem, we will not be able to solve it.

We all have our part to play – by reducing plastic going in to our seas and then removing it once it is there.

You can see more on the problem here.

We quote some of the provocative statements from the programme notes here:

““We quantified and estimated that 8 million metric tonnes of plastic entered the ocean (in one year).” Environmental Engineer

“Submarine pilots know when they are at the bottom of the sea because they see the plastic.” Environmental Scientist

Four Corners brings you this thought provoking story from French filmmaker Vincent Perazio in which he examines the work of these scientists investigating our plastic waste.

Some are undertaking research to see if plastic is making its way into the food chain, others are looking into the impact on marine life and the environment.

“It’s not worth throwing away plastic bags. You should just season them well and eat them directly because they’re going to end up back on your plate in one way or another.” Marine Scientist

“Once there is so much plastic in the seas, there is nothing to eat for the filter feeders, for the fish, for the whales.” Oceanographer

As a species – we tend to follow the mantra – “out of sight, out of mind”. However, there are lots of great options available now for recycle bottles and cans – see our blogs on recycling in Australia and environmental companies.

Also see our blog on biodegradable plastic bags in commercial bins.

Note: Coca Cola recently announced they would be boosting the recycling plastic component of their drinks bottles.

Conclusion:

Our oceans are so vital for the future of the planet and of course in Australia – 90% of us live within a short drive of one!

Plastic pollution is a serious threat to ocean life – and our way of life also. See our blog on building a green company.

Check out the short cartoon below showing how much plastic is in the ocean – the figures will amaze you:

How Do Recycling Plants Work?: ♻️ Podcast Ep. 12 Don’t Be A Waster

Listen on Apple Podcasts Listen on Spotify Listen on Google Podcasts Listen on Stitcher Listen on Amazon Music

In this episode of our podcast we look at how MRFs work – i.e. Material Recycling Facilities – also called Material Recovery Facilities.

These are very large facilities that separate recycling streams so they can be recycled.

Transcript – How recycling facilities actually work!

Hello and welcome to another edition of our regular podcast on all things recycling. It’s called Waster or actually it’s not called that. It’s called Don’t be a Waster: Recycle and of course you’ll find this podcast and all leading all your leading platforms from Spotify to you know Amazon to Google’s podcast etc and of course on YouTube and in today’s episode we want to we’re going to look into the question as to how does a recycling facility work and when we say our recycling facility we are talking about a recycling separation plant or in the industry they’re called MRFs often material recovery facilities and these are basically facilities that separate the waste streams the recycling streams from mixed recycling collections and separate them out into the various streams and then from those once they’ve been separated then they can go to actual recycling plants so we will discuss I suppose the importance of these facilities first of all and then give you a bit of an overview as to how they work and you know I’d be all I’d also recommend anyone who gets the opportunity to visit one they should really take up the chance because they’re quite interesting.

I’ve been to them a number of times and I think even in Sydney I know that certain school groups can visit them in certain areas just to have a look and to gain education about it so I suppose why do we need these facilities to separate recycling the first the first reason is that we have you know what we what we call co-mingled or mixed recycling bins the yellow bin that you’ll be used to at your house that you’re you know your residence or also in business and these bins can they’re very versatile bins because they contain multiple waste streams you can put containers whether plastic you know milk containers you can put canned aluminium cans you can put some cardboard boxes you can put count of tomatoes etc so they’re quite versatile and with that versatility you know you don’t have to think too much about them you don’t need a separate bin you can throw a lot of the products into the same bin and have confidence that they will go off and be recycled which means we need fewer trucks.

You know a you don’t have to put as much effort into separating things b we don’t need as many trucks to bring them to the facilities and it just increases the chance that these items will be recycled so obviously I think you can see the issue here if you’re putting various waste streams into the same container into the same bin sooner or later we have to separate them so it’s you know once you mix things up sometimes unmixing them can be even more tricky so you know one of the most important things you’ll note about your commingle bin is that you don’t use bags so we do not use plastic bags to contain the materials the cans the bottles except for the glass bottles you just you just put them in the bin as they are and you know just throw them into the into the naked bin and then with that it goes into the truck.

The reason for this is that if you bag the materials if you bag them at all it will make it significantly more difficult to actually empty them it will make it will make it harder to separate them out and so that’s why if you do bag stuff in a commingled bin chances are it will be rejected by the truck you know you’ll have to wait for the next collection so this is because once things are bagged you can’t see what’s in the bag and it just makes it super difficult to separate so that’s rule number one once you go to the recycling facility and these we call them MRFs or material materials recycling facilities they are I suppose they’re basically like huge warehouses is what they look like from the outside very large buildings generally square or rectangular style buildings very large and the trucks the commingled recycling trucks will come up, they generally don’t crush the materials to a large extent not in the same way that you would get in a in a general waste truck but they so it’s the stuff will be empty and more loose and then once you get there the trucks will dump the materials onto some format some loading dock or a conveyor system that will enable the waste of the recycling materials to start processing through a conveyor belt system.

Through different I suppose different what we call separation mechanisms and some of these are quite interesting in the way that they use you know they use gravity they use shape they use size anywhere some like quite not exactly the most modern systems sometimes but a simple technology applied to separate out the various streams so you know I’ll give you a brief overview obviously you know on a podcast format it’s it might be more useful to actually see this visually but we will cover this in a in a variable format knowledge and we will provide notes in the you know in the show notes etc so where you can go and see additional information on this topic so yeah so once we start off we you start on the conveyor belt system and the materials are dumped onto that at a certain speed and the first thing we generally would have is we would have people called pickers who would be standing on either side of the line you know wearing protective clothing.

Wearing gloves, aprons you know goggles those sort of things just because you need to be protected from say broken bottles anything that shouldn’t be in the bin and of course we all know things get dumped in bins they shouldn’t be there from syringes to you know the jagged cans of different things so the pickers will be wearing protective gear and they will their job at the beginning is to separate out any large visibly you know items that should not be there that will mess up the separation systems that we will get into further down the line so that’s the first human element that goes into it and that’s a screening a screening approach that that removes stuff also paper and cardboard can be removed at this point in time because obviously cardboard boxes are quite large and they can be pulled out from the system and pushed along next and obviously the order that this occurs in could be different in different facilities.

Next one we’ll say we’ll go through a glass processing where glass is separated by size and obviously different sizes of bottles and different colours and it’ll be separated out often through mechanisms such as trommels etc where glass will be heavier than other items and it will fall to the bottom all you know plastics and stuff that would be generally lighter and this will enable separation so once you remove the glass it will generally be crushed and sent off to a recycling facility where it would be recycled into new glass products and of course we’ve covered in previous podcasts that glass is infinitely recyclable it can be recycled over and over again and there’s no requirement to add new glass to that.

Paper and cardboard as we mentioned then will be separated out they also will be sorted and shredded and sent off generally to a cardboard recycling facility so as we’re reducing down the volumes or the quantity of items you know the actual mechanisms of recycling becomes less manual and probably a bit more mechanical and using technology aluminium processing and would be probably next I think we covered in a previous podcast how aluminium is you know if you’re going to recycle a single item let’s go with aluminium cans because it’s incredibly reusable infinitely recyclable and it saves huge amounts of energy which are required to make new aluminium by smelting it from bauxite so aluminium is separated by using an eddy current which then extracts all the aluminium cams from the process and then a centre recycling plant next we get into plastic processing so high quality plastic streams will be sorted and again this is generally through gravity style mechanisms whereby things are can be dropped and there’s quite a bit of ingenuity to this we’ll link to some videos in in the in the notes whereby you know the materials will go up a slope and then items will drop back based on their on their densities on their weights etcetera.

That enables quite efficient separation and then movement onto processing so after that we move into steel processing obviously there’ll be some steel contained in the bins and we in the rubbish and we’ll be utilizing aspects such as electric magnets which will simply just pull the metal aspects out of the remaining waste streams and then that is again sent to a metal recycler so if you think about this along the processing along the conveyor belt items are dropping out of different positions they’re dropping out of different places along the line and then at those places they’re being you know bailed compacted and processed either on site if it’s a very large facility or more likely shipped to a specialist recycling facility for that exact waste stream so you know the paper and cardboard goes to the paper and cardboard facility, aluminium and so on and so on.

I suppose these plants are required obviously there will always be also some general waste at the end based on contamination based on items may be very small items that that can’t be recycled and let’s be honest you can constantly improve these facilities there are items that will not be recycled through these facilities such as bottle tops things like that which can be recycled if we build facilities and collection mechanisms but in 2022 its they will generally go to landfill or general waste so there’s constant room for improvement these are by no means perfect systems or 100% foolproof systems but they have very effective mechanisms to separate out you know the vast majority the large percentages of what we put into them so you know I think I hope you found this interesting I think this will we’ll also link to some videos etc in our show notes and show how this can work really give you a feel as to the size you know the you know the systems in place for separating waste.

Some of them are quite ingenious so we will leave it there today I think you know in in many of our upcoming podcasts we’ll cover some of the technology in the waste industry how things are done and I think if you understand how things are done it’ll give you an understanding as to how some of some of the bottlenecks in the recycling process we all want to recycle more and more but you know a lot of times it’s the practical issues are can only become apparent when you see and look into the issue but sometimes when you appreciate what those practical issues are it gives you an understanding and then we can help I suppose as a society move on to maybe you know find better answers and rectify some of these problems by fixing some of these bottlenecks so I’ll leave it there today and again we leave you with a slogan recycle don’t be a Waster.

Leave a Reply Cancel reply

Product categories

Most Popular Posts

-

Commercial Waste Management Services: Reduce Waste Collection Costs! 🚍

-

Medical Waste Disposal: Everything You Need To Find Out In 2024! 💉

-

Rubbish Removal Sydney 2024: Better Bin Collections For Business ✅

-

Clinical Waste Disposal 2024: What To Know About Business Clinical Waste ⚕️

-

Secure Document Destruction 2024: All About Security Bins Shredding 🔒

-

Free Cardboard Recycling 2024: Can I Get Free Cardboard Collection? 📦

-

Confidential Paper Disposal Bins 2024: What You Need To Know About Shredding! 🔒

-

Recycling Bins Australia 2024: Recycling Can Boost Your Profits! ♲

-

Commercial Wheelie Bin Collection: What Businesses Need To Know In 2024 🗑️

-

Commingled Recycling 2024: Why Commingled Bin Is Key To Recycling 🍾